We live in the world of NOW! In a winner-take-all world, the companies that have real-time, agile operations throughout their entire value chain will prevail. Add real-time operational intelligence to your enterprise processes and OEM products. Decisions that you need to make can now be made in real-time. Today!

Our customers are using Interstacks to:

Increase productivity by remotely monitoring machines in real-time to measure utilization (OEE – Overall Equipment Effectiveness). Monitor up/down time, count parts and machine cycles, track quality. Record reasons for downtime.

Reduce maintenance costs by pro-actively scheduling maintenance based on usage and sensor data.

Improve quality and yield by building custom QA stations.

Optimize field maintenance truck runs for OEM products via remote monitoring.

Differentiate their OEM products and add new business model options by adding IoT monitoring features to existing and new products. Talk to us about our private labeling partnerships.

And many other innovative applications of the industrial internet of things (I IoT or Industry 4.0 ). Use cases are only limited by your imagination!

![]()

Rapidly deploy your industrial IoT (Industry 4.0) project in a low risk, non-disruptive way. No IoT or software expertise needed.

Join other Interstacks users in digitally transforming your enterprise. Email us now at info@interstacks.com

Sensor OEM

The leading manufacturer of bearing reliability sensors uses Interstacks private label hardware and MyStacks IoT cloud to deliver a complete bearing lubrication solution to their global 2000 customers. When bearing wear is detected, a signal is automatically sent to a lubrication canister mounted on the equipment to dispense grease.

Utility Cable Manufacturer

A large manufacturer of electric utility cable uses a proximity sensor to count revolutions of cable making machines’ take-up reels. A real-time view of all of the factory’s machines is viewed on the MyStacks IoT cloud platform.

Optics Manufacturer - OEE

A manufacturer of high-end laboratory equipment uses a power consumption sensor to monitor lens polishing machines up/down time resulting in increasing productivity. An analog-in block connects to the power sensor and a Wifi block is used to send the data to the MyStacks IoT platform.

Water Treatment OEM

A maker of water treatment equipment uses an Interstacks stack with a RS-485 block and cellular data connection to get data from the PLC inside the equipment and send it over the cell network to the MyStacks IoT cloud platform. Maintenance runs can then be optimized.

CNC Shop

A CNC shop connects “job done” and “job alarm” digital outputs to a stack. A text message is sent if the outputs are triggered, thus enabling “lights out” overnight runs.

Battery Manufacturer

A manufacturer of batteries uses Interstacks to get information from scales and micrometers to monitor manufacturing quality in real-time. A RS-232 block interfaces with the equipment and ethernet is used to connect to the factory network.

Get PLCs Connected

Connect a data output port (RS-232, RS-485, Ethernet) or other PLC output (switch closure, analog output port) to a stack to indicate machine status. Attach external sensors like power consumption. Send the PLC and sensor data together. Use a cell network block to remotely monitor PLCs from anywhere.

Add remote monitoring to OEM Products

Add remote monitoring to new or existing products by embedding a stack or adding on in the field. Contact us about our private labeling partnerships for hardware and IoT cloud dashboards. Send usage and maintenance data to the MyStacks central dashboard to increase customer engagement and enable usage based business models.

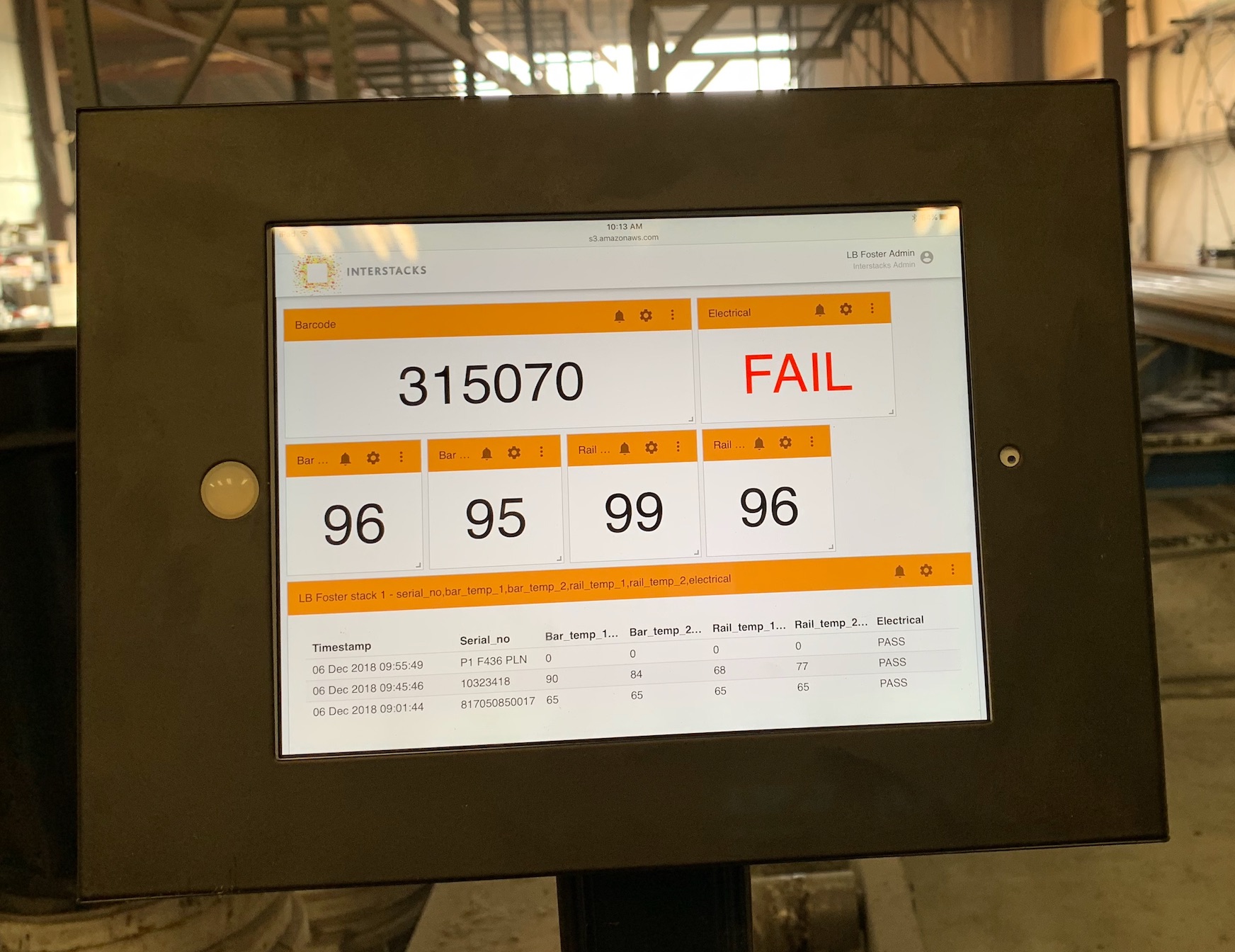

QA Data Collection

Barcode scan a serial number, collect data via QA tests using sensors, then do a final pass/fail test. All data is timestamped, displayed, and sent to the dashboard for visualizing and saving in a permanent database. Now any field failures can be traced back to the original manufacturing process.

Monitor Solar-Battery Units

An OEM of mobile solar-battery products remotely monitors voltages and current draws. Real-time streaming of voltages (up to 70V DC) and current (up to 500A) is sent via cell data along with GPS location to the MyStacks IoT cloud dashboard.