Interstacks News

Interstacks News – Vibration monitoring, Use Cases, MyStacks additions, Digital In

Wireless Vibration Monitoring

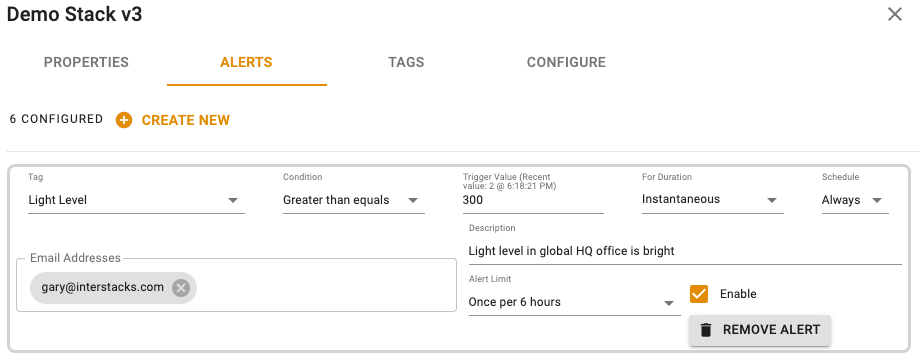

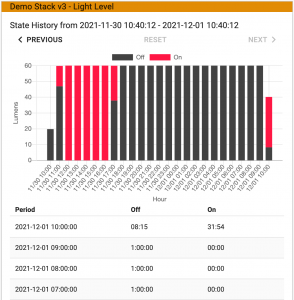

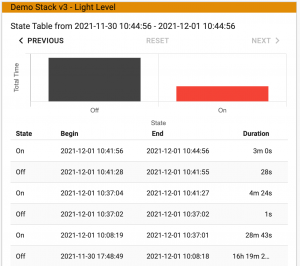

Machine, pump, and motor operating conditions are often indicated by their vibration characteristics. Well before a failure or stress reveals itself in a complete breakdown, vibration anomalies can be detected. Interstacks’ new wired and wireless vibration monitoring starter kits make it easy to capture real-time vibration data, view it on the MyStacks dashboard, and get real-time text/email alerts based on that data. The wireless kit uses a bluetooth vibration sensor and the wired kit uses a RS-485 digital data sensor. email info@interstacks.com for more information.

Vibration Monitoring Starter Kits

Solar Panel-Battery Monitoring

Interstacks is now being used to capture real-time voltages and currents from mobile solar panel-battery units. The GPS location of the mobile unit is also sent to facilitate theft detection. Real-time input and output, voltages and currents are sent to the MyStacks dashboard over the cell data network. This deployment can sense DC voltages up to 70V and DC currents up to 500A. This is another example of an industrial OEM using Interstacks to add remote monitoring features to their existing product.

Monitor Solar Panel-Battery Starter Kit

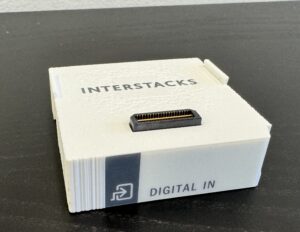

Digital In Hardware block

As part of our continued R&D investments, we have added a new hardware block for 0-30V digital inputs. This block has four opto-isolated inputs with separate grounds. This is sometimes used to input PLC digital outputs or other machine outputs, for example from CNC machines.

Digital In Block

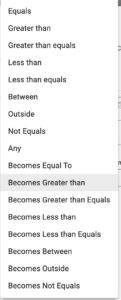

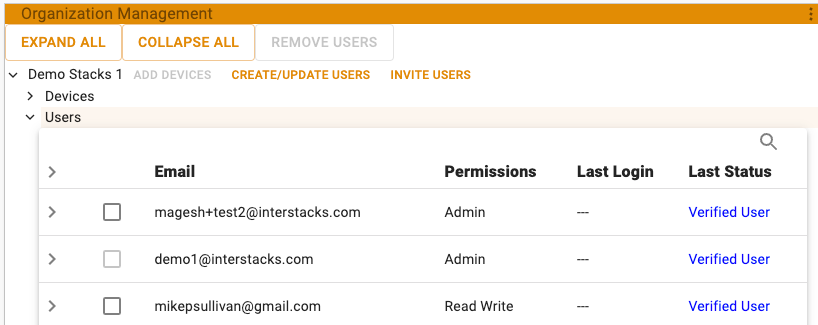

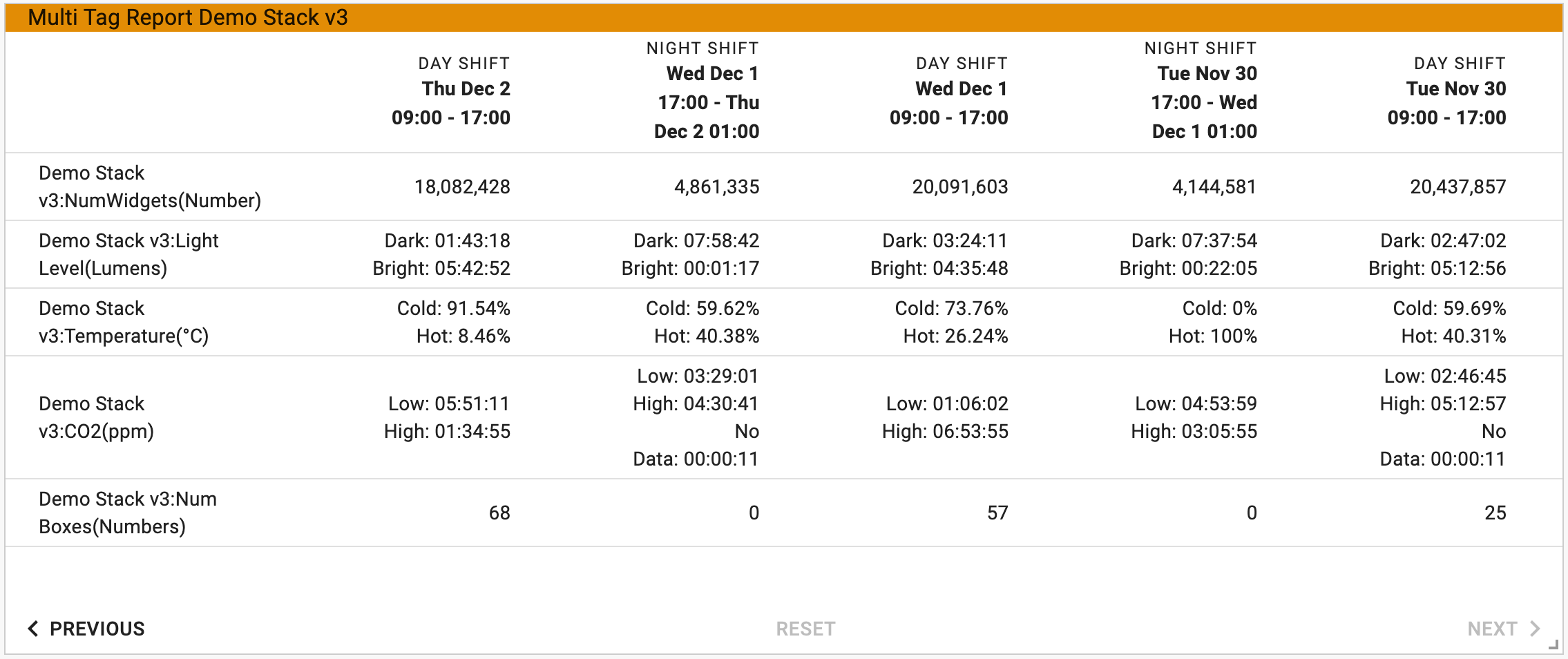

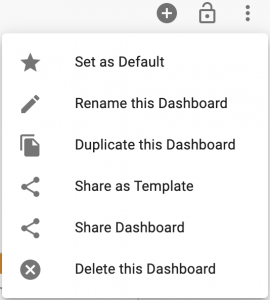

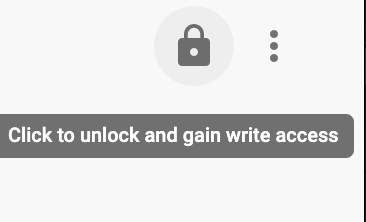

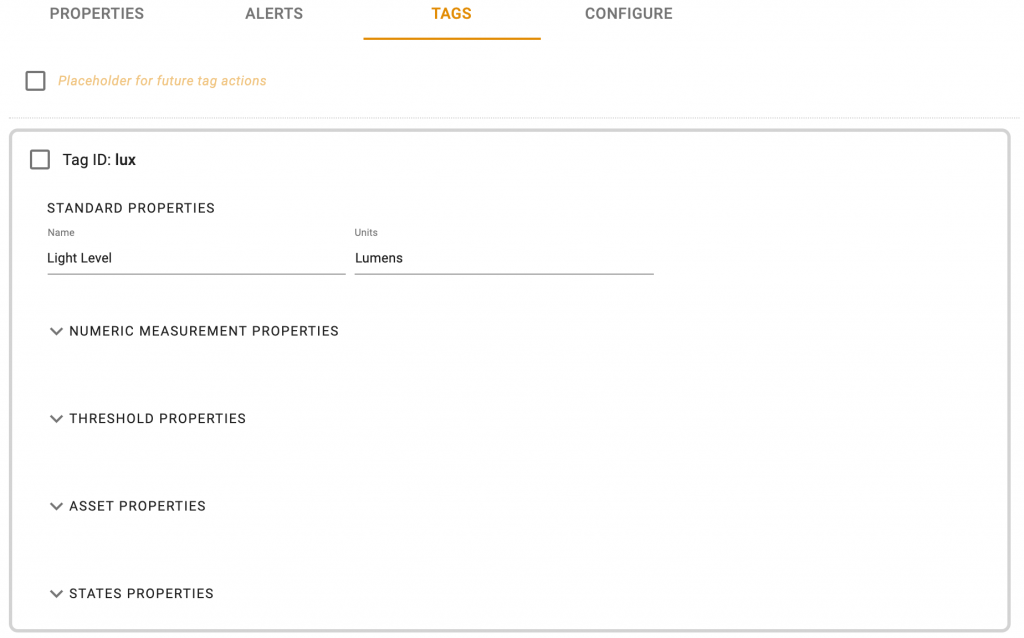

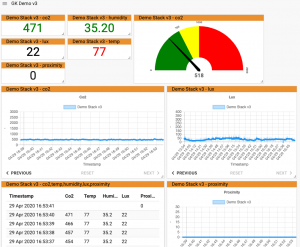

MyStacks New Features

One result of our ongoing investment in product development is that the MyStacks IoT cloud platform is always getting new features based on customer input. The most recent additions include: more alert condition options, multi-factor authentication (MFA) login options, more direct ways to add users to organization accounts, and performance improvements for large dashboards.

Webinar Feb 8

We will be doing a webinar on Feb 8th 2024 titled “How IoT can work for you – Capture data in manufacturing to improve productivity and reduce maintenance costs”. This is part of an education series from a manufacturing consulting and training organization called Catalyst Connection. Catalyst helps many manufacturers in Pennsylvania improve their operations.

Contact Us

Please email us at info@interstacks.com to discuss your machine and sensor monitoring projects. Or adding IoT features to OEM products – we private label hardware and MyStacks cloud dashboards for OEMs. Our engineers and system designers would love to talk with you about your projects.